There is much going on in the world of hydraulic, pneumatic and electric motion systems, from technology introductions and industry advancements to new trends and industry leaders. Each week the Power & Motion team collects the latest industry news to help keep our readers up to date on what's happening in the fluid power and electric motion control sectors as well as the industries they serve.

NAM Calls for Better Policymaking from Regulators

The National Association of Manufacturers (NAM) is voicing its concern about the regulations being placed on automakers in the U.S. Today there are a number of fuel standards, emissions and other regulations which are making it difficult for automakers and their suppliers – including fluid power manufacturers – to stay on top of them all.

Pain points the association points to in a press release include there being too many regulators, brief timelines and mandates on the types of products which can be produced, such as battery-electric vehicles.

To help alleviate this issue for both manufacturers and consumers, NAM states in its press release it would like policymakers to follow four key steps:

- Harmonize standards.

- Set realistic targets.

- Provide reasonable timeframes.

- Protect consumer choice.

Schaeffler Merging with Vitesco to Become a Leading Motion Technology Company

Schaeffler AG has entered into a business combination agreement with Vitesco Technologies Group AG that will see the companies bringing their expertise together to become a leading motion technology company. Doing so will enable the companies to further expand their technology portfolios, with a particular focus on electrification solutions.

The combined company name will be Schaeffler AG and will bring together the strengths of both companies. Efforts are being made to create as smooth a combination of company cultures and employees as possible.

Four divisions will comprise the newly combined company:

- E-Mobility

- Powertrain & Chassis

- Vehicle Lifetime Solutions

- Bearings & Industrial Solutions.

The E-Mobility division will be headed by Thomas Stierle, who currently leads Vitesco’s Electrification division. The additional divisions are:

"At Schaeffler, we are fully convinced that both companies ideally complement each other and will thus be stronger together. We are pleased that, after intense and, in part, for both sides challenging discussions, we came to a business combination agreement, which now lays the ground for a swift and effective integration. This is an important milestone on our way to creating a leading Motion Technology Company," said Klaus Rosenfeld, CEO of Schaeffler AG, in the company's press release announcing the merger.

READ MORE: How Company Mergers Bring Expanded Market Opportunities

Siemens Introduces New Simulation Tools with AI Capabilities

Siemens Digital Industries Software has introduced two new engineering simulation software tools, HEEDS AI Simulation Predictor and Simcenter Reduced Order Modeling. Both are designed to provide more predictive performance with greater speed, precision and efficiency according to the company.

HEEDS AI Simulation Predictor enables engineering teams to utilize artificial intelligence (AI) driven predictive modeling for faster design iterations. Advantages offered by this software tool include AI with built-in accuracy awareness to precisely fine-tune and optimize product designs. It self-verifies predictions to ensure simulations are accurate and reliable.

Historical simulation studies and accumulated knowledge can also be used within the software to quickly iterate designs which helps manufacturers bring products to market faster.

Simcenter Reduced Order Modeling uses high-fidelity simulation and test data to train and validate AI and machine learning (ML) models which allow engineers to perform predictions in a fraction of a second states Siemens in its press release announcing the launch of the new software tools. Training of the AI/ML models enables more trustworthy, reliable and robust insights to be gained for better overall simulation and eventual product designs.

"HEEDS AI Simulation Predictor and Simcenter Reduced Order Modeling represent a true breakthrough in simulation technology. They enable our customers to take advantage of benefits of artificial intelligence-driven simulation to speed their exploration of a design space and to do so accurately and robustly," said Jean Claude Ercolanelli, Senior Vice President, Simulation and Test Solutions at Siemens Digital Industries Software, in the company's press release. "It also enables them to not only use these breakthrough technologies on new projects, but to leverage decades of past simulation data to help deliver new insights on current projects."

READ MORE: How Machine Learning Could Aid the Design Process

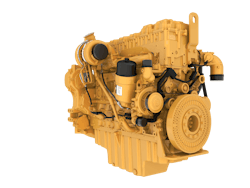

Caterpillar Developing Hydrogen-Hybrid Power Solution

Caterpillar Inc. is launching a 3-year program to demonstrate the capabilities of a hydrogen-hybrid power solution for off-highway machines. The company intends to show how state-of-the-art control systems and electric-hybrid components can enable hydrogen fueled engines to meet, or exceed, the power density and performance of traditional diesel engines.

For the project, Caterpillar will be using its 13-liter Cat C13D engine platform which was introduced at CONEXPO-CON/AGG 2023. The engine is desigend to provide up to a 20% increase in power and up to 25% more low-speed torque compared to previous generations. It allows use of renewable liquid fuels such as biodiesel, suiting its use for the hydrogen project. Caterpillar also designed the engine to be adaptable for future technology advancements, further benefiting its use for the project.

Hydrogen is seen as a potential alternative fuel option in many heavy-duty machine applications because it can better meet their power density requirements. It is also an abundant resource and only produces water vapor as an emission, making it desirable diesel alternative. However, there remain challenges with producing it in a cost-effective and environmentally friendly manner as well as a need to build up fueling infrastructure and technology challenges which have yet to be overcome.

Some in the fluid power industry have told Power & Motion that with hydrogen engines, there may not be as many changes needed to hydraulics or other systems in a machine like there often are with battery-electric power systems. Therefore, hydrogen engines could provide a more feasible alternative which does not require a lot of design changes for OEMs and their suppliers.

Research is expected to commence in the first quarter of 2024 and is supported in part by funding from the U.S. Department of Energy’s (DOE) Vehicle Technologies Office (VTO) through the Office of Energy Efficiency and Renewable Energy (EERE). It is one of 45 projects to recieve funding aimed at advancing research, development, demonstration, and deployment of solutions which can reduce greenhouse gas (GHG) emissions in the transportation sector.

READ MORE: Hydrogen-Battery Hybrid System Drives World's Largest Mine Haul Truck

Daimler Delivers 20 Battery-Electric Trucks

Daimler Truck North America has delivered 20 zero-emission Freightliner eCascadia Class 8 battery-electric trucks to its customer Reyes Coca-Cola Bottling (RCCB). These will be the facility's first electric vehicles in its fleet.

In addition, 20 of the company's Detroit eFill commercial charging stations have been installed at the facility to enable recharging of the trucks. RCCB worked closely with Daimler to ensure the right vehicles and set up were chosen to fit its needs, ensuring optimal returns on its investment and ease of integration.

Daimler states in its press release announcing the delivery that its trucks' have a design optimized for electrification which includes the in-house developed Detroit ePowertrain and various battery and drive axle options. The trucks can provide a typical range of 155, 220 or 230 miles depending on the configuration while charging time is about 2-1/2 to 3 hours in order to reach 80% capacity.

The delivery signifies the continued growth of electric vehicles in the market, particularly regional and shorter haul applications where electric-powered heavy trucks currently make the most sense due to the shorter travel distances and ability to return to a base to recharge.