There is much going on in the world of fluid power and motion control, from technology introductions and industry advancements to new trends and industry leaders. Each week the Power & Motion team collects some of the latest industry news to help keep our readers up to date on what's happening in the industries in which they work.

igus Develops Digital Universe to Showcase Products

The new iguverse from motion plastics company igus provides a digital universe in which it can present its products. This igus metaverse will feature digital twins of the company's products as well as enable its engineers to more easily work with customers from around the world.

Future editions of the iguverse will include 3D models of products which allow for a 360-degree panoramic view. Customers will also be able to experience various igus facilities, such as its test laboratory in Cologne. All of this helps to provide a more realistic, life-like experience for customers to help improve their ability to select products and design appropriate solutions.

"The iguverse represents a new way of presenting, selling, and engineering. It has plenty of potential for future sales. For many, the metaverse is still uncharted territory," said Frank Blase, CEO of igus, in the company's press release announcing its digital platform. "We also want to learn more and are traveling this path with our customers. For example, salespeople and customers could wear VR glasses during customer visits and immerse themselves in the iguverse.

"Studies show that customers are up to nine times as likely to remember experiences in virtual reality and thus understand things better," added Blase.

TCCI Testing Center to Benefit EV Development

Compressor developer TCCI Manufacturing is building a state-of-the-art research and development facility to aid with the development of electric vehicles (EV). The Climatic Center for Innovation and Research (CCIR) will support testing, technology advancement and full-scale climatic testing for high-voltage systems, battery cooling and A/C as well as heat pumps.

Having these testing capabilities will enable the company and its industry partners to ensure development of systems which operate safely. Cooling in EVs is important due to the heat generated by batteries and other components; while TCCI's compressors aid with cooling, other components and systems can impact performance. The new testing facility will help to understand full vehicle systems to ensure optimized EV designs.

WATCH MORE: Higher Voltages Call for Increased Cooling Capacity

TCCI received funding for the CCIR as part of a tax incentive program from Illinois to aid manufacturing of EVs in the state. The company expects construction of the facility to be completed in 2024.

Epiroc Acquiring Collision Avoidance Technology Company

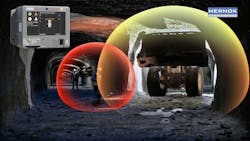

Mining equipment and technology manufacturer Epiroc will acquire South Africa-based Mernok Elektronik which develops collision avoidance systems for mining applications. The acquisition will help further expand Epiroc's safety and automation technology offering.

Mernok Elektronik designs proximity detection and collision avoidance systems which meet some of the highest safety standards for the mining industry. The technology can be utilized on a single machine or in a mixed fleet containing machines from various OEMs, providing flexibility to mine operators.

These types of systems are vital to ensuring safety, particularly for those working around the large machines used in mining applications. They are also important components for the development of autonomous vehicles as they help machines see objects and people on the work site.

New Bosch Rexroth Factor Automation Customer Innovation Center

Bosch Rexroth has made another investment in its North America operations with the opening of a new customer innovation center located near Austin, TX. This comes after announcing a new plant in Mexico and expansion of the company's operations in North Carolina.

The new innovation center will be geared toward factory automation customers from various industry segments such as electric vehicle manufacturing, consumer packaged good and semiconductor manufacturing. Known as the Rexroth Customer Innovation Center (CIC), the facility encompasses about 9,200 sq. ft. and includes various exhibits and presentation areas.

At the CIC, customers can learn about Bosch Rexroth's factory automation technology as well as industrial hydraulics products. Interactive demos offer scaled versions of complete production lines using various automation solutions, such as the ctrlX AUTOMATION platform, autonomous mobile robot, and smart hydraulics.

A state-of-the-art engineering lab is also on site where customers can work with Bosch Rexroth team members to address technology needs.

"The new Customer Innovation Center gives our factory automation customers an opportunity for a unique, customer-focused experience, providing a space where they can interact with and learn about our current and future innovations to move their manufacturing operations forward," said Bosch Rexroth North America President and CEO Greg Gumbs in the company's press release announcing the opening of the CIC.